Steps Ahead... Stock Optimization

This is a no-nonsense software based approach to achieve optimal inventory levels for your company. An inventory level that best suits your sales pattern and taking into account the delivery reliability you require. But also with a minimal capital invested in the right part of your product range: the part that has the highest contribution to your sales margin (fast runners).

This is a no-nonsense software based approach to achieve optimal inventory levels for your company. An inventory level that best suits your sales pattern and taking into account the delivery reliability you require. But also with a minimal capital invested in the right part of your product range: the part that has the highest contribution to your sales margin (fast runners).

Smaller and medium-sized enterprises (up to a turnover of approximately EURO 150 million) have difficulties in achieving optimal inventory control in a practical and manageable way. Inventory management is in our view a "managerial issue". This means that the stock composition and level is the result of the visions and actions of different staff members. From the perspective of the financial manager holding stocks results in capital investment and financing issues. The sales officer looks at the stock position as an "asset" to be able to supply customers directly and preferably without back orders. The purchasing officer looks at the stock position to achieve the best possible purchasing conditions (for example, by obtaining volume discounts). The logistics officer associates stocks with logistic movements, etc. No wonder that stock optimization is perceived as difficult by many companies !

When we analyze the stock positions of companies, we often see a picture in which the stock is too wide (too many products with too low contribution), (much) too high, that working capital is invested in parts of the stock that deliver a low or even negative (dead stock) contribution to the operating results, that there is an sheer intuitive and insufficient quantified approach of managing the stock development, lacking consensus between the aforementioned officials about what should be the optimal inventory level and how to achieve that, etc.

Our experience is that companies are able to achieve a stock reduction of about up to 60% while delivery reliability can be improved significantly. It is evident that on one hand this leads to a substantial reduction of the amount of working capital needed, and on the other hand this leads to significant operational improvement due to lower costs of keeping stocks, reduced financing costs, lower handling and logistics costs, lower risk of obsolescence, lower insurance costs, lower opportunity costs, etc. The rule of thumb is that the costs of keeping stocks (depending on the nature of the products) are between 25% and 35% of the purchase value of the stock.

We use a highly practical approach in clear and simple steps, supported by specialized Steps Ahead... analytical software. Step by step and in close cooperation with our clients and based on thorough mathematical analysis of the inventory situation and its development (taking into account the companies sales patterns, purchase policy, cost of stock management, desired delivery reliability, etc. ) we determine optimal stock positions per article and stock reduction potential per article. And ofcourse the necessary measures to achieve this.

Among others we can deliver the following:

A. Quick-Scan: for a fixed fee we will analyze your stock position and report:

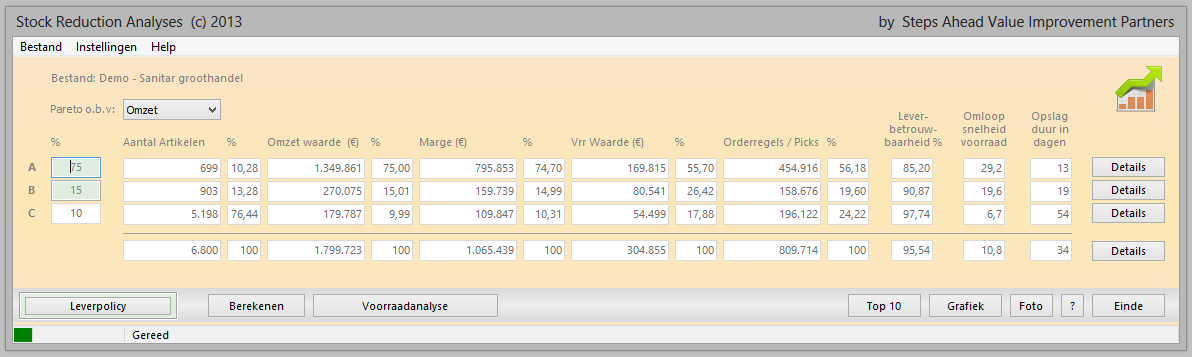

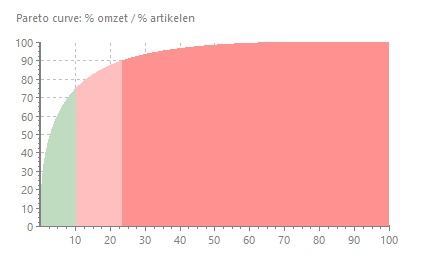

- ABC analyses on product level on basis of different criteria to choose

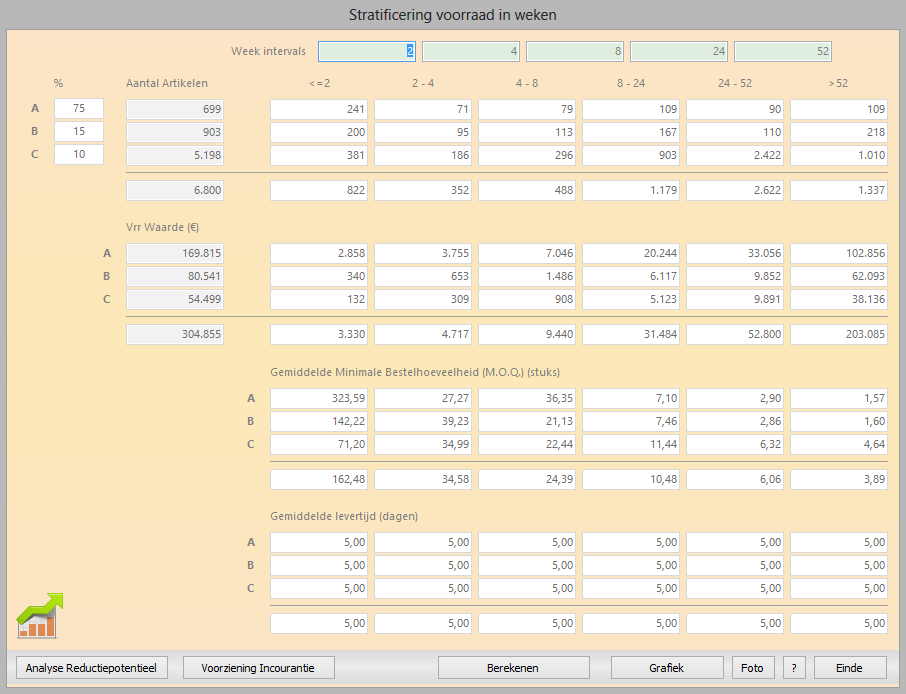

- analyze the composition of the stocks on product level including the relation between sales volumes and stock positions

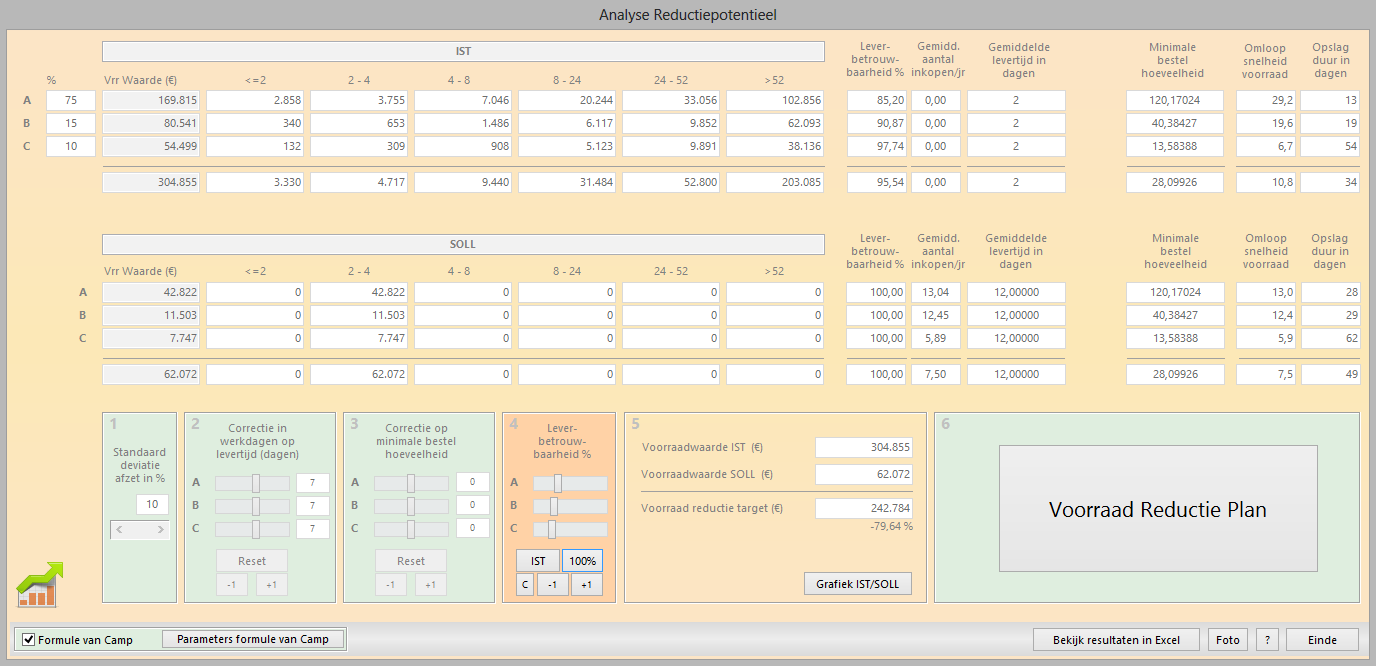

- mathematical analyzed inventory reduction potential including the impact on operations and liquidity

- IST - SOLL analysis per product and in total

- optimized order levels and order quantities for each item

- the delivery reliability based on the current and future stock positions

- advise how to achieve the calculated reduction potential

- the current dead stock situation

- calculation of an adequate provision level for obsolete products

- the impact of reducing purchasing lead times and minimum order quantities from suppliers

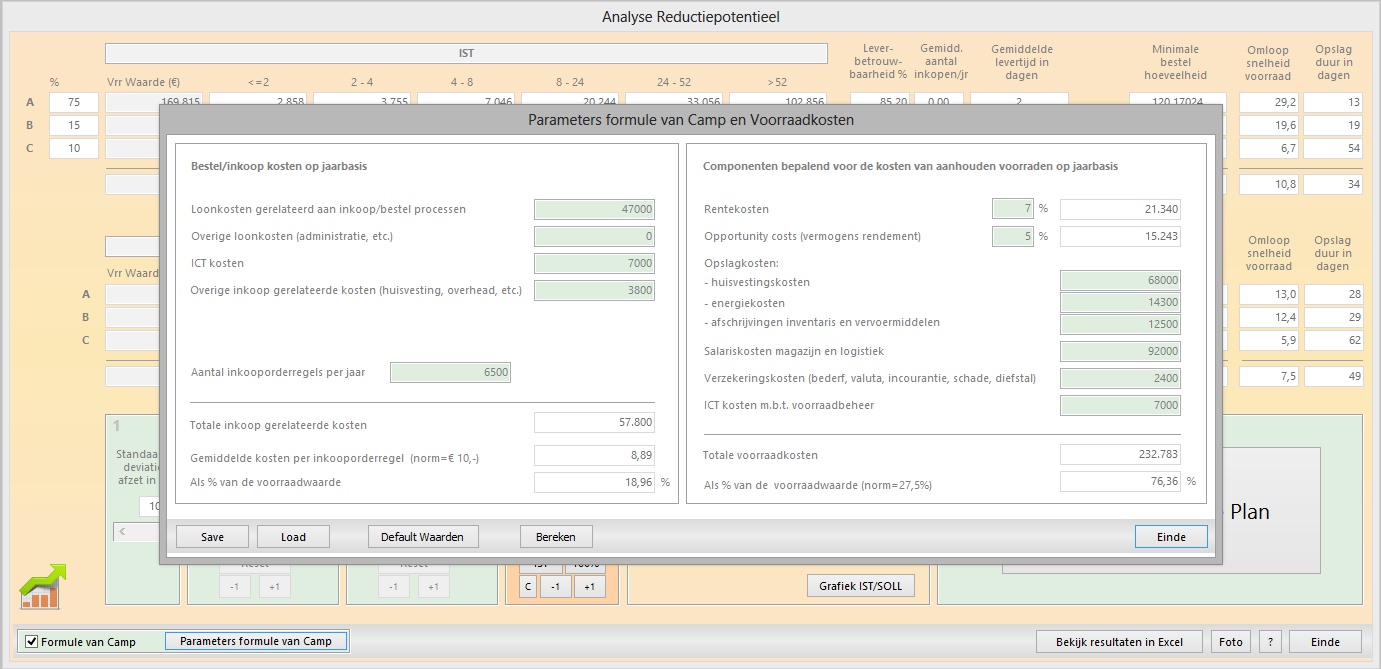

- the costs of stock handling and the reduction potential herein

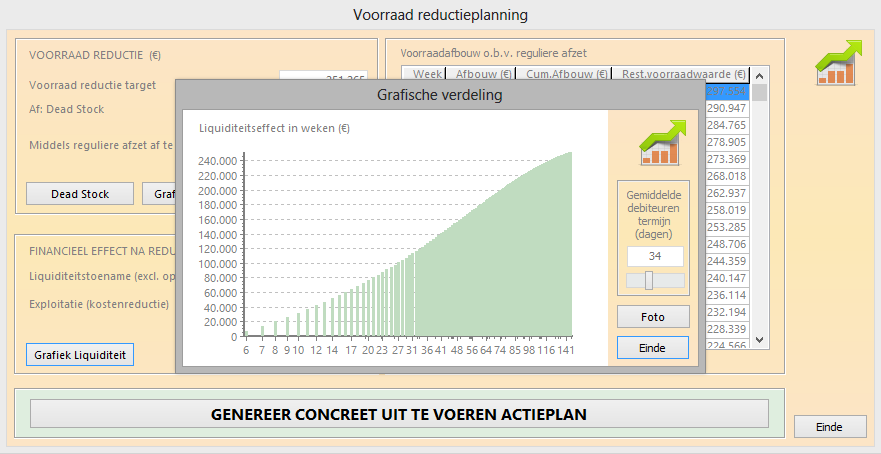

- stock reduction scheme on weekbasis including the resulting liquidity improvement.

On basis of this Quick-Scan you will get a clear picture of the companies stock situation and the potential to reduce the actual stock position and the measures that have to be taken to achieve this.

B. Implementation support: we will periodically support you in the execution and monitoring of necessary actions, we will advise you in specific issues, are your sparring partner or act as a process manager to be sure to achieve and keep the desired optimization level.

Steps Ahead... Analytical software

Our software has a huge range of analytical tools, under which:

- ABC analyses on individual or a mix of criteria

- What-if analyses

- calculate the effects of shortening delivery times, changing the purchase cycle, changing the minimal order quantity (MOQ) per product, changing the desired delivery reliability, etc.

- determine per product the optimal orderlevel and the optimal order quantity

- analyse dead stock position

- calculate liquidity effects of changing stock positions during time

- generate exception lists

- etc.

Hereafter a couple of screens are presented as an illustration.

Read more about: